Optical CMM Solutions for Automated 3D Quality Control

Designed for automated quality control applications, the R-Series™ 3D scanning solutions are perfect for manufacturing companies who want to increase their productivity by measuring more dimensions on more parts without compromising on accuracy in shop-floor environments.

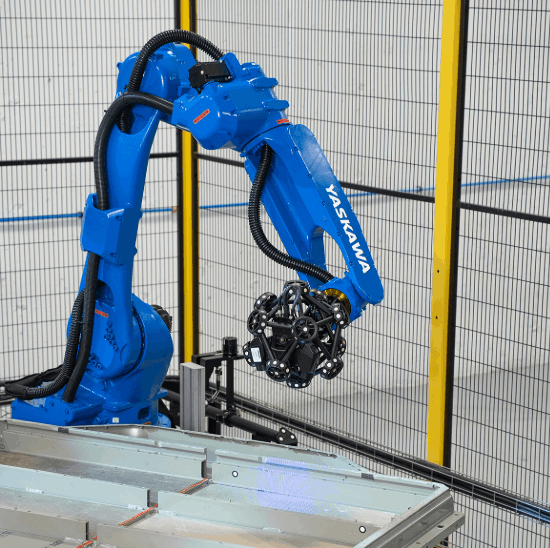

The MetraSCAN 3D-R™ is a powerful, innovative series of robot-mounted optical CMM scanners that can be seamlessly integrated into automated quality control processes for at-line inspection in mass production. Its cutting-edge technology enables manufacturing companies to detect quality issues faster.

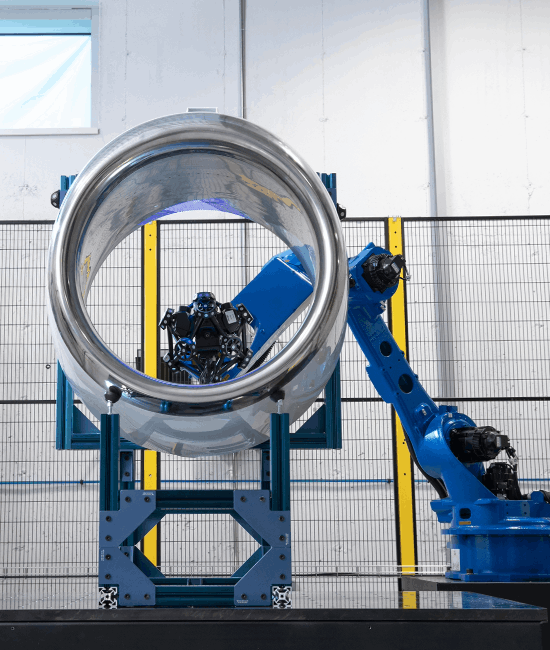

The CUBE-R® leverages the power of the MetraSCAN 3D-R in a high-productivity industrial measuring cell that has been designed to be integrated into factories for at-line inspections. Compared to traditional CMMs, the CUBE-R is much faster, providing a gain in productivity and better efficiency.

Contact us today for more information!